Stock Code

002851

- Home

- About

-

Products

-

MIG/MAG Welding Machines

- Regular MIG/MAG Welders

- Pulse MIG/MAG Welders

-

Ultra-low Spatter MIG/MAG Welders

-

- Artsen Plus D/P/Q Series Intelligent Platform MIG/MAG Welders 350/400/500A

- Artsen Pro Series Intelligent Platform MIG/MAG Welding Machine

- Dex2 L D/P/Q Series Hardware Ultra Low-splash MIG/MAG Welders 350/500A

- Dex2 M D/P/Q Series Multi-functional Software Low-splash MIG/MAG Welders 350/500A

- Megwave H Series Hardware Ultra Low-splash MIG/MAG Welders (Dex2 L CE)

- Megwave S Series Multi-functional Software Low-splash MIG/MAG Welders (Dex2 M CE)

-

- Cold Arc MIG/MAG Welders

- TIG/GTAW Welding Machines

- MMA Welding Machines

- SAW Welding Machines

- Carbon Arc Gouging Welding Machines

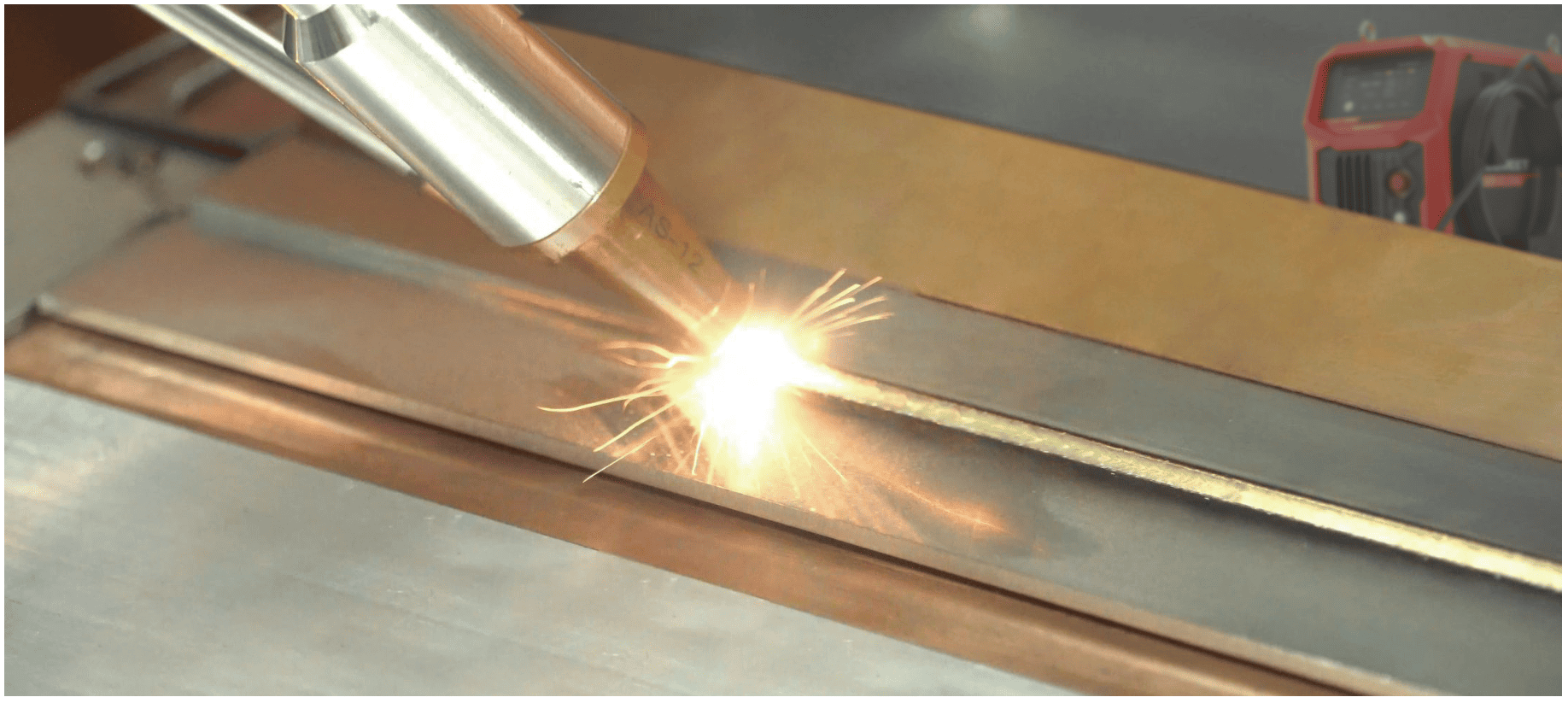

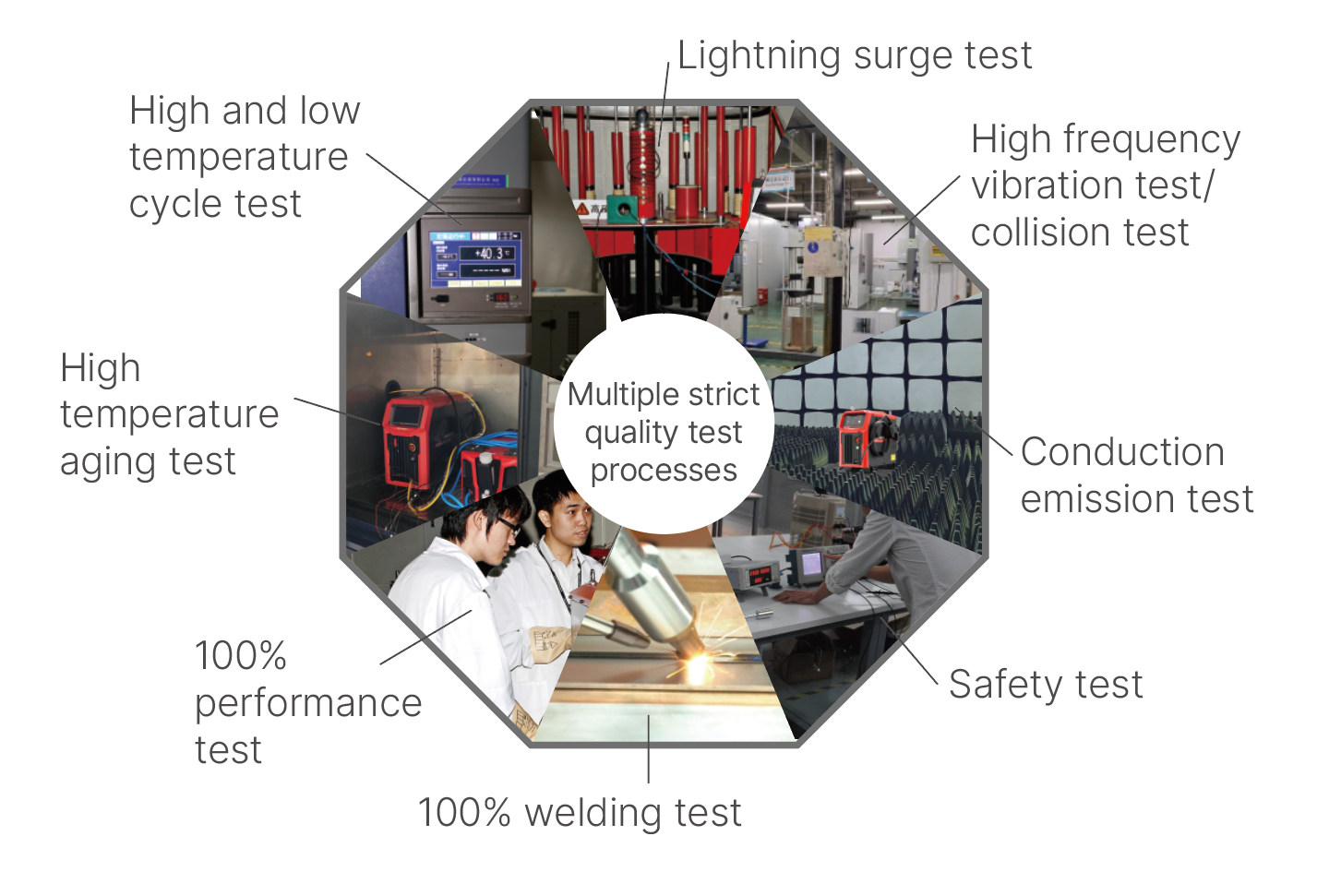

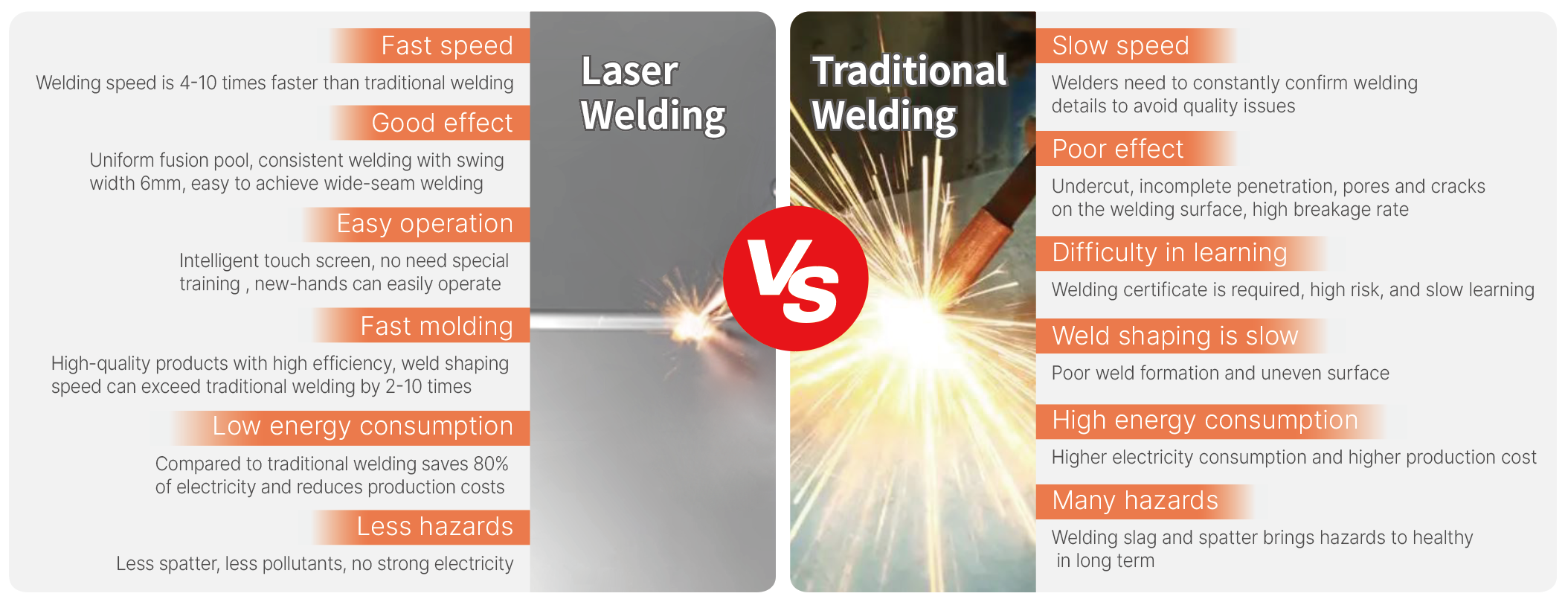

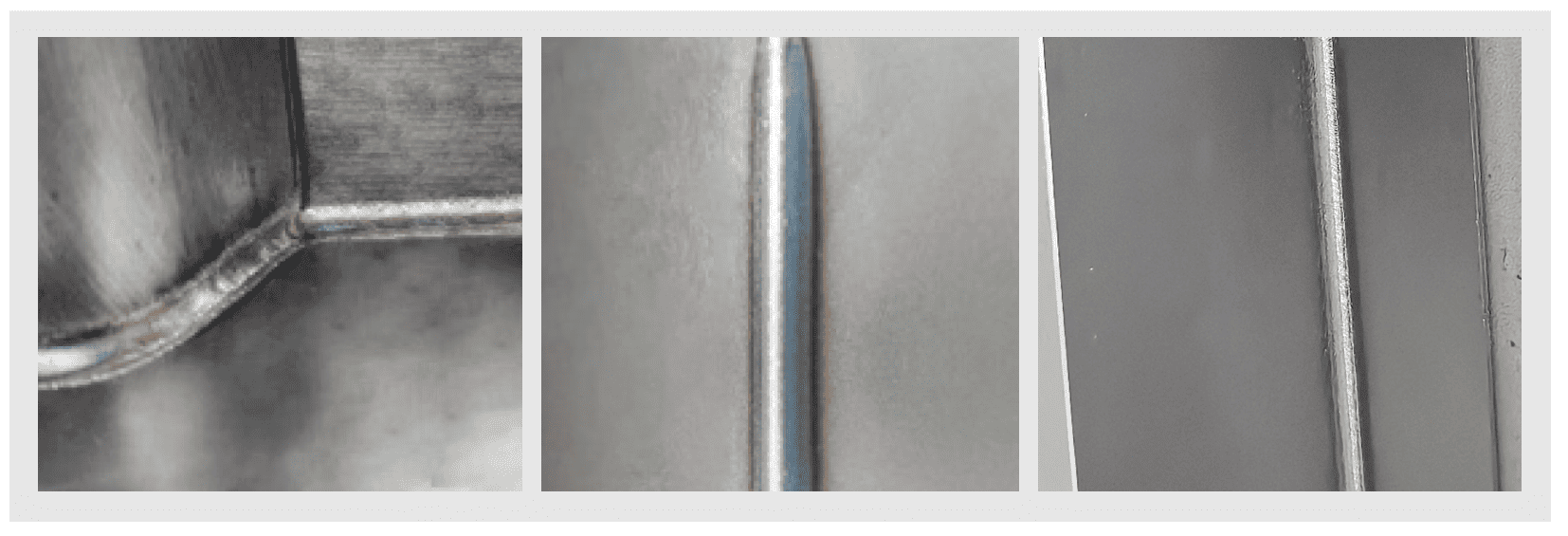

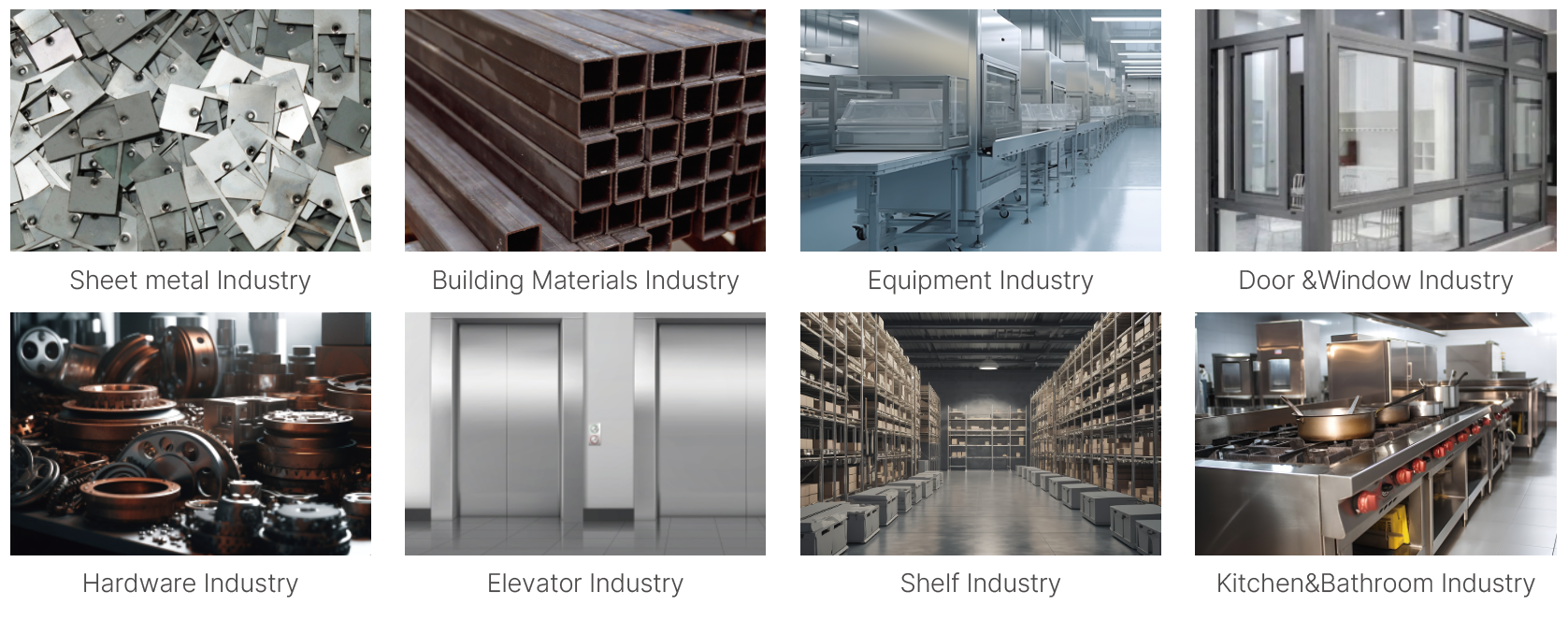

- Laser Welding Machines

- Robotic and Automatic Welding

- RDT Cold-Transfer High-speed Servo Welding Technology

- SMARC Intelligent Welding System

-

Torches, Wire-feeders and other Accessories

-

MIG/MAG Welding Machines

- Solutions

- Data download

- Contacts